06, 2019

by oreelaser

We know that the most common laser cutting methods include: laser vaporization cutting, laser melting cutting, laser oxygen cutting and the laser scribes and controls the fracture.

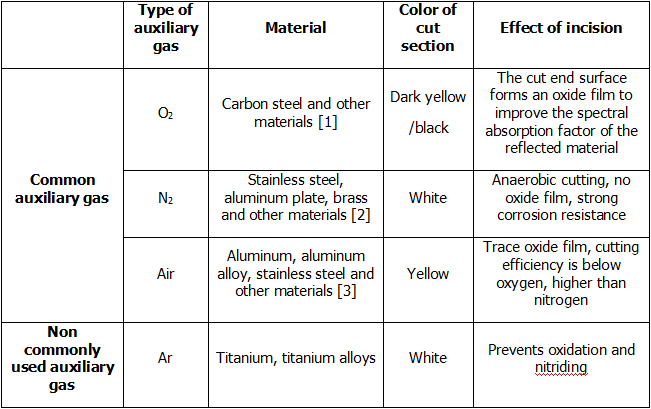

The auxiliary gases with the highest frequency of contact are: oxygen, nitrogen and air. Argon is expensive compared to those three types gases and the cutting range is small.

The auxiliary gas corresponds to the material one by one, and the cutting effect layer formed on the surface of the slit is also greatly different. Please refer to the following form:

[1] Rolled steel, rolled steel for welding construction, carbon steel for mechanical construction, tool plate, stainless steel, plating plate, copper and copper alloy, etc.

[2] Stainless steel, plating steel plate, brass, aluminum and aluminum alloy, etc.

[3] Aluminum, aluminum alloy, stainless steel, brass, plating steel and nonmetal, etc.

Next, let's look at the factors that influence the cutting effect:

(1) Low purity of auxiliary gas

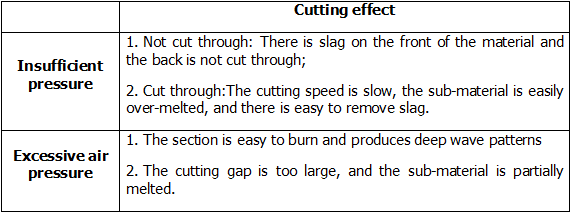

(2) Auxiliary gas pressure

In addition, according to the relevant data, the appropriate auxiliary air pressure variation law is:

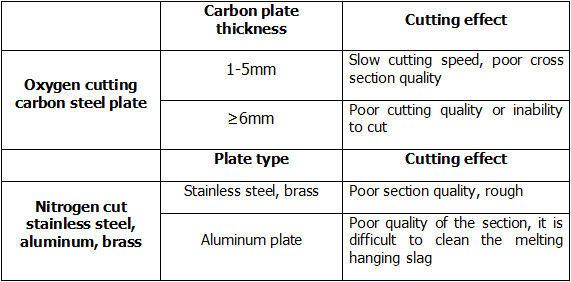

When oxygen is used to cut carbon steel plate, when the thickness of the thin plate is increased from 1 mm to 5 mm, the cutting pressure range is sequentially reduced to 0.1-0.3 MPa. , 0.1-0.2MPa, 0.08-0.16MPa, 0.08-0.12MPa, 0.06-0.12MPa;

And when the thickness of medium-thick carbon steel sheet is increased from 6mm to 10mm, the corresponding auxiliary gas pressure range is sequentially reduced to 0.06-0.12MPa, 0.05 -0.10 MPa, 0.05-0.10 MPa.

When a nitrogen (auxiliary gas) cut stainless steel plate (thickness increased from 1 mm to 6 mm), the cutting pressure was changed from 0.8-2.0 MPa to 1.0-2.0 MPa to 1.2-2.0 MPa, which was a high pressure cut.

Professional Laser Cutting Machine Manufacturer - OreeLaser